Precision and power: Innovative solutions for steel processing

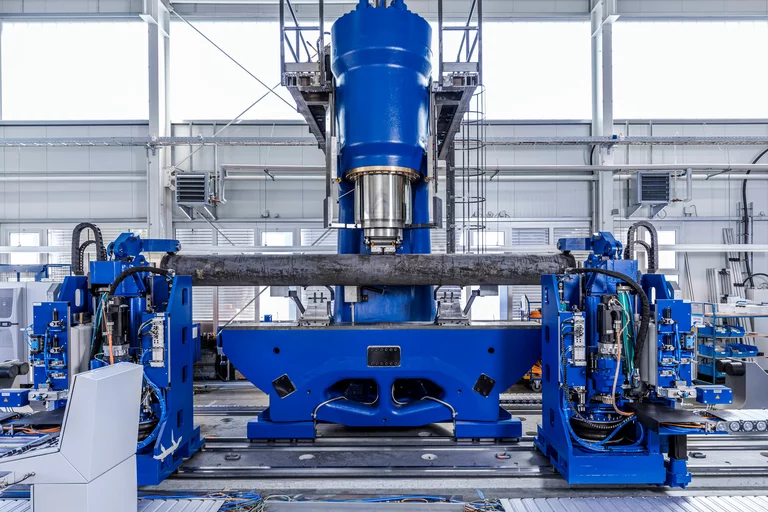

With the new ASV 2000-8000 straightening machine, MAE is taking steel processing to a new level and setting new standards in the industry thanks to maximum efficiency and smart digital control. Steel bar is a special form of steel that is produced in long, straight bars with different cross-sections and is used in numerous industries, such as aviation, automotive, mechanical engineering, transport and logistics.

Whether hot or cold steel, large diameters or considerable lengths – the powerful straightening machine ensures maximum precision and quality. With this machine, warped steel bars are a thing of the past.

A partnership that has set new standards

Together with Slovenian steel company SIJ Metal Ravne, the specialists at MAE developed a fully automated solution for straightening steel bars. The ambitious project promised not only higher product quality but also a significant increase in production efficiency.

It all began with a reference visit to BGH in Siegen. There, engineers from SIJ Metal Ravne joined MAE to see first-hand the ADSV 4000 installed by MAE – an impressive 4,000-tonne straightening press that has been in reliable service since 2015/16. With its ability to straighten steel bars with a diameter of up to 800 mm and a length of 20,000 mm, it has already set new standards in the industry.

This visit marked the start of an outstanding project that also broke new ground for MAE, as Slovenia had not previously been on MAE’s radar as a significant market. Originally with strong roots in the automotive industry, the main markets were primarily in Hungary and Romania. However, with SIJ Metal Ravne, MAE discovered an important player in the steel industry in Slovenia – an opportunity that could not be missed.

A special kind of challenge

It quickly became clear that this was no ordinary project. The scale of the plant was unprecedented: delivering an automatic straightening machine of this size to Slovenia was a first for MAE. The machine standalone weighs almost 50 tonnes – a load that pushes many crane systems to their limits. This was also the case in Slovenia. Once there, it became apparent that the existing crane capacities were insufficient.

Additional special equipment had to be delivered to the construction site at short notice in order to safely lower the heavy machine into the prepared pit. It was a logistical masterpiece that was mastered with meticulous planning, team spirit and technical precision. Without the excellent cooperation between all those involved in the project, especially the MAE employees and the support of Ravne, particularly in the area of logistics, the success of such a demanding project would hardly have been possible.

The close and cooperative partnership made it possible to drastically reduce the design phase, which would otherwise have taken several years, to just 13 months until the start of production. With a project volume of EUR 4.35 million, the plant is the largest single project to date at the state-of-the-art site in Erkrath.

MAE – Specialist for precise metal straightening

Over 90 years of experience

MAE has stood for engineering expertise "Made in Germany" since its foundation in 1931.

Expert for levelling machines and wheel presses

Innovative solutions for maximum precision.

In use worldwide

More than 1,000 installed systems for optimum production quality.

Technological edge through digitalisation and complete interlinking

MAE’s travelling stand straightening system sets new standards in automation: it is the first travelling stand straightening machine to be built after a complete redesign with the state-of-the-art RICOS control system, enabling an even more precise straightening process and raising the quality of the finished steel to a new level. In addition, MAE is offering a complete solution for this demanding project for the first time on its own, with the support of an external partner, including all conveyor technology – thus creating significant added value for the customer.

Discover the MAE Group with its industrial machines, comprehensive services and global locations on the company website.

“With our first fully automatic levelling machine in Slovenia, we have not only opened up new markets but also demonstrated our innovative strength.”

Claas Jorde

Managing Director MAE Maschinen- und Apparatebau Götzen GmbH

The company’s profile

| 2024 sales (in € millions) | 39.4 |

|---|---|

| Staff (31.12.2024) | 149 |

| Participation rate GESCO SE | 100 % |

| Member of the GESCO Group since | 1997 |